Many times, we take for granted the tools we have at our disposal on our job sites and in our workplace. Cranes and other hoisting equipment are all too often tools that we take for granted. We look at the massive amounts of weight and variety of materials that they are continually handling, with what looks like ease.

But there are so many factors that go into these calculations of what a crane can lift and move about the workplace. Are you familiar with what may affect your crane’s ability to move the materials that are expected of it?

But there are so many factors that go into these calculations of what a crane can lift and move about the workplace. Are you familiar with what may affect your crane’s ability to move the materials that are expected of it?

What is your role on the job site you are working on? Is there a crane involved in the operations taking place? What do we need to be picked up, moved, or placed with the crane we have available?

The ability to read a crane capacity or load charts are so critical that even minor changes will have a massive bearing on what the crane can do.

What are the ground conditions of the site we intend to place the crane on?

What is the weight we expect to apply to the crane, and how far do we need to go with it?

Just because you have a 300 Ton Capacity Crane, does not mean that everywhere it can reach, it will be able to handle that “maximum” amount of weight. This can only be achieved in the ideal conditions for that crane, in its maximum configuration, at its shortest radius. Determining the highest amount of weight to be hoisted is the first step in ascertaining the correct crane for the job.

Counterweight plays a

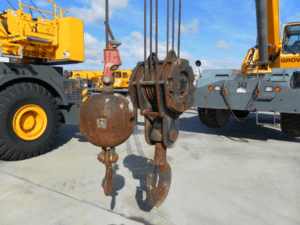

Parts of line are another major deciding factor on a crane’s lifting abilities. This is achieved by the mechanical advantage of blocks and pulleys. Each part of line has its individual capacity.

If you do not have the correct amount of cable capacity, you will never reach what the crane is capable of doing.

The difference of one part of line to ten parts of line can be hundreds of thousands of pounds. Always be aware of what a single part of line can lift on its own, and the effects of multipart reeving on your machine.

Attach

These are just a few of the limiting factors of crane capacity.