The world’s strongest man is only as strong as the ground he is standing on. Standing on a solid surface he can lift the world; stand on a sandy beach the amount he can lift is significantly less. A crane’s outrigger set up is no different and when done properly you will maximize the crane’s lifting capacity.

Proper set up of the crane is critical during hoisting activities, regardless of the size crane and/or weight of the load. Blocking and proper matting will distribute the weight of the crane and the load over a greater surface area. This increase surface area will then reduce the amount of ground bearing pressure which improves the stability of the crane.

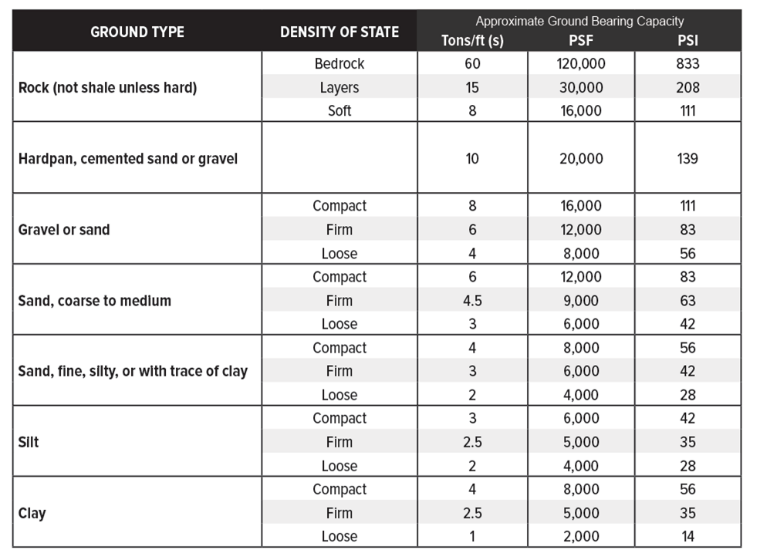

Keep in mind that ground bearing is only part of the equation. The amount of ground bearing pressure from the crane must be less than the bearing capacity of the surface of the ground or bearing surface.

You will see a couple examples below of how much pounds per sq.ft a crane will project on the ground with proper matting and without.

Example, the maximum outrigger load which occurs is 146000 lbs. under the front corner outrigger. Since the machine is equipped with 24” diameter outrigger pads, the bearing pressure under the pad can easily be calculated as:

146,000 lbs.

——————————– = 46,496 sq.ft

(24in/2)2 x 3.14

Using 4’x4’ crane mat:

146,000 lbs.

——————————– = 9125 sq.ft.

4×4

Even a 4×4 mat would not be a proper on some soil types. The above calculation is a loose example and a geo-technical expert should be consulted to address soil conditions and the soil’s ability to support the load handling equipment.

Here are a few other safety tips for proper crane set-up.

- Ensure cranes outriggers are extended per manufacture’s specification

Understand the crane’s quadrants of operations. The quadrants of operations with the most lifting capacity is typically the area opposite the engine compartment

When position a crane, plan to make your farthest or heaviest lift in the strongest quadrant

- The most common quadrants of operations are:

- Over the side

- Over the rear

- Over the front

- 360 degrees

- When firm footing does not exist proper support of cribbing shall be used

- Remove machine weight from tires. If unable to do this due to site conditions then on the rubber load charts should be used

- Do not place blocking under outrigger beam

- The blocking material must be of the size, amount, condition and method of stacking the blocking must be sufficient to sustain the loads and maintain stability

- Outrigger pads and dunnage should be able to support total weight of the crane and load

- Outriggers and stabilizers must be visible to the operator during extension and setting or a signal person must be used

- Ensure cranes are leveled with one percent of grade. A crane 3 degrees off level will decrease capacity by as much

To learn more about proper crane setup, crane stability, and more about crane safety, then drop into one of our classes to learn from industry-leading experts here at Colorado Crane Operator School