Mobile, tower and overhead cranes are some of the most expensive and important pieces of equipment on any site today. Cranes can cause serious damage if they are not used correctly – and they can be even more dangerous if the machinery itself malfunctions. This is why crane and rigging inspections are required to ensure equipment is safe to use.

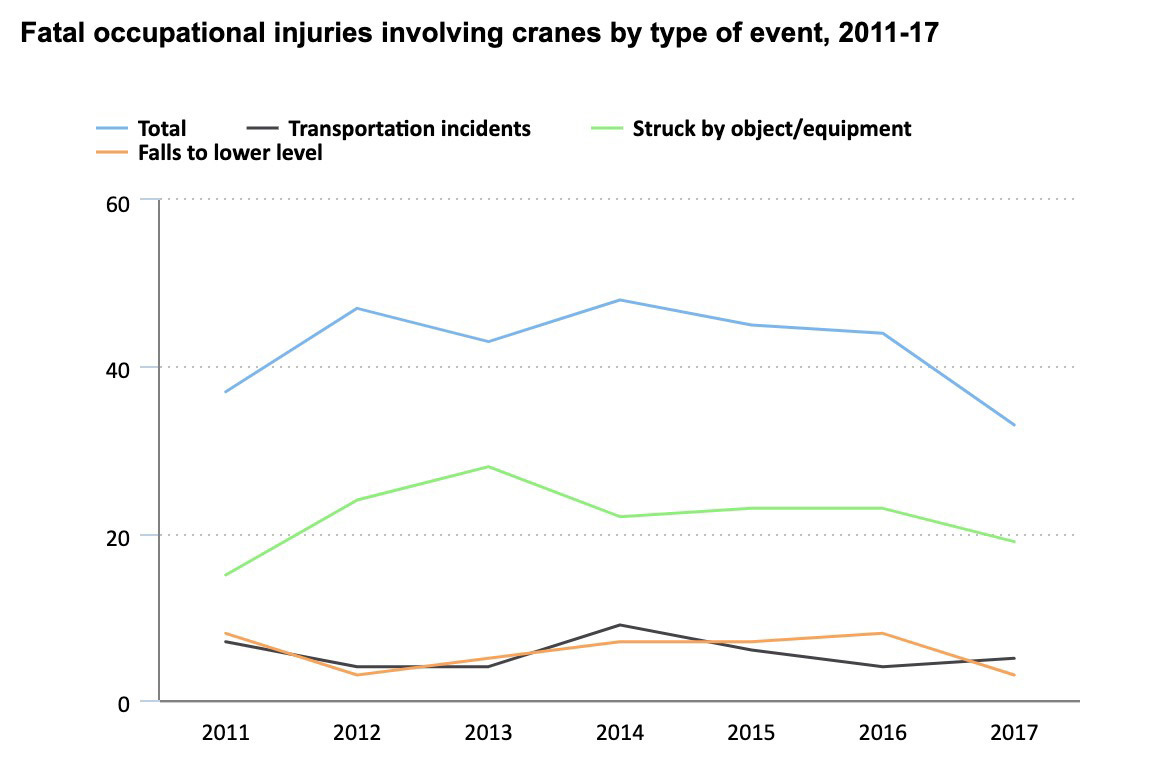

Thankfully, additional OSHA requirements on inspection and training have helped to reduce the number of annual injuries involving cranes. There are different types of crane and rigging inspections that OSHA requires, depending on the circumstance, situation, and type of equipment.

All inspections must be carefully documented and completed by a qualified person – such as someone who has the knowledge, training and experience to conduct inspections and most likely completed crane operator training and classes for inspections.

Failing any of these inspections can slow down production until the problem is resolved. It is important to know what to expect during all kinds of crane and rigging inspections to eliminate any issues that could result in violations.

So, here is what to expect during the crane and rigging inspection process so you can avoid unwelcome surprises.

Equipment Inspection

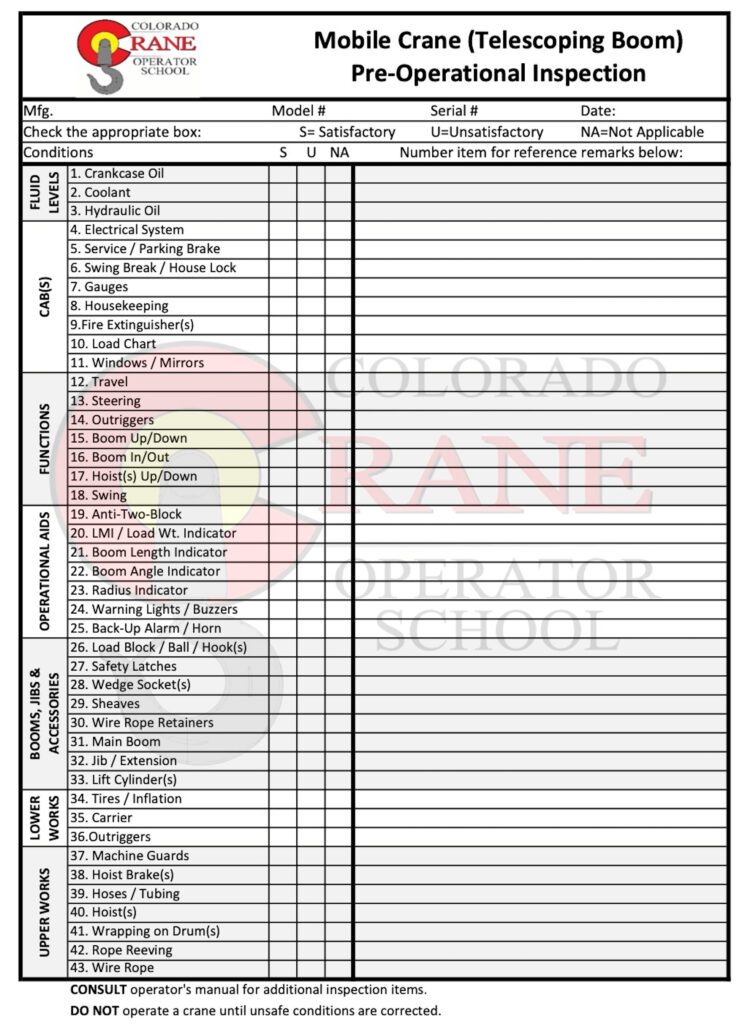

A Mobile, Tower, Overhead and Mini Crane is required to be regularly inspected. Many construction firms will use a pre-written checklist for frequent inspections to ensure all of the most important parts are checked. This includes checking fluid levels, tire inflation, and lifting parts such as the hoist or crane neck.

Any parts that appear to be damaged and need an adjustment, repair, or replacement is noted during this inspection. This is also used to monitor parts that wear down over time, such as the tires, hinges, or rust-prone areas.

Tag Inspection

OSHA requires that a Lockout/Tagout system be used to display important information on hazardous energy equipment. These tags will include the date of the last inspection or important information, such as a part being “in service.”

Some tags are inspected and replaced annually. The inspection card color changes from year to year, so it is easy to identify any tags that have expired. These tags are designed to make the inspection process easier and to keep accurate records.

It is extremely important to make sure all tags are labeled, secured correctly, and replaced according to the required schedule. Lockout/Tagout issues are one of the top five most common OSHA violations for construction sites!

Daily Equipment Operability Determination

An initial equipment inspection is required before each use of a crane. OSHA requires daily inspections to be completed by a competent person, meaning someone familiar with the crane equipment as well as any hazards.

First, the surrounding area of the crane should be checked to ensure that there are no physical hazards in the proximity. This includes measuring the space from the crane’s path by power lines, trees, or other buildings, as well as other workers.

Next, the rated capacity of the crane will be checked and compared to the load weight. Then the hoist, trolley, bridge, runway, and electric systems will be inspected and tested for broken parts.

The powered systems of the crane will be checked to ensure that the control buttons are operable and functional. The hoist hook buttons, upper limit switch, and other important push button controls need to be tested. Any structural damage or external issues should be noted. This includes dents, scratches, or cracks on the crane itself.

Finally, important safety factors will need to be checked. This includes noting any signs of oil spills or leaks and testing the motor brakes. Important indicators and gauges which measure calibration, wind speed, and load weights must be functioning properly. There should also be a working fire extinguisher in the operating cabin of the crane.

Wire Rope Inspection

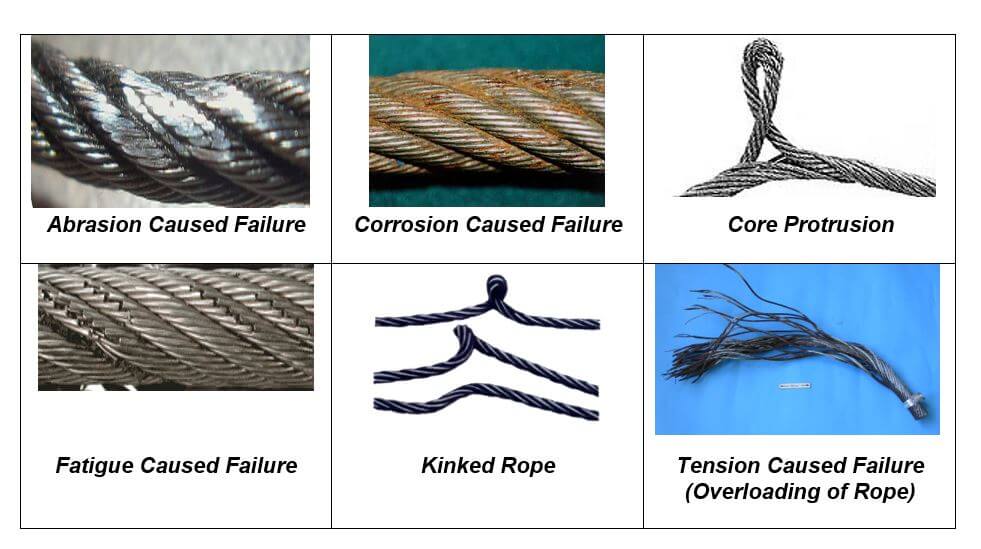

Any wire ropes used on a crane regularly should be inspected daily. If the wire rope has not been used in over one month, it must undergo a thorough inspection before it can be utilized again.

Wire rope can wear down easily if it is used or stored incorrectly. For instance, using too much weight or lifting and stopping loads too quickly can increase the friction and break down the wires.

Inspectors will be on the lookout for any signs of damage. This includes fraying, birdcaging, corrosion, kinks, or damaged fittings. Some of these issues can be repaired, but a full replacement may be necessary under some circumstances.

Inspectors will also look to see if the wire rope is seated in the drum grooves correctly so that it moves smoothly and does not twist. If the wire rope is attached to lifting equipment pieces (such as a hook block), the contact point must be carefully inspected for signs of excess wear.

Slings

Slings are a crucial piece of overhead lifting equipment as it is used to secure loads to the crane itself. Sadly, the majority of fatal injuries involving cranes occur due to issues with load securement. If the sling breaks or is not connected correctly, the falling load could injure or even kill workers in its path.

Therefore, slings must be inspected every time they are used. This should be done before the rigging crew has secured the load. Any new slings must undergo a proof test and inspection to ensure that it can hold its rated load capacity.

Rigging Accessories

All overhead lifting and rigging hardware must be thoroughly inspected before use. This includes:

- Hooks

- Shackles

- Turnbuckles

- Eyebolts

- Swivel hoists

- Rigging blocks

- Wire rope clips

Before any of the equipment is used, a competent person should visually inspect the hardware to look for signs of wear, distortion, or damage. This includes looking for any irregularities, rust, or misshapen parts. One bent turnbuckle or damaged shackle could cause a major crane accident – this is a crucial aspect of crane and rigging inspections.

Conclusion

Proper crane and rigging inspections can help to reduce the number of accidents on construction sites significantly. But these inspections are only effective if they are conducted according to OSHA’s regulations by people who know exactly what hazards to look for.

At Colorado Crane Operator School, we offer specialized classes and training to help operators learn the procedures for daily, regular, and annual inspections. We teach a variety of courses for crane and rigging operation and offer NCCCO certification testing.If you are interested in learning more about these classes, please contact the Colorado Crane Operator School team.